Products & Technology

Principle Of Bearing

Even in ancient times before the invention of any kind of machine, it was known to everyone that a heavy object could be moved more easily if rollers were placed beneath it than by simple pushing or pulling. This is clearly seen in a relief from the ruins of Nineveh, made in about 650 B.C which shows a cart and people moving stone with the help of rollers.

This is clearly seen in a relief from the ruins of Nineveh, made in about 650 B.C which shows a cart and people moving stone with the help of rollers.

KEY INDUSTRIES

| Automotive Aerospace Railway Wind Energy Machine Tool Pumps & Compressors Electrical Motors Electrical Power Tools Construction Machinery Conveying & Handling Mining & Mineral Processing |

Gears & Transmissions Food and Beverage Plastic ,Rubber and Packaging Fans & Blowers Pulp & Paper Textile Chemical Farm & Forestry Super Precision Skates & Racing Household Appliances |

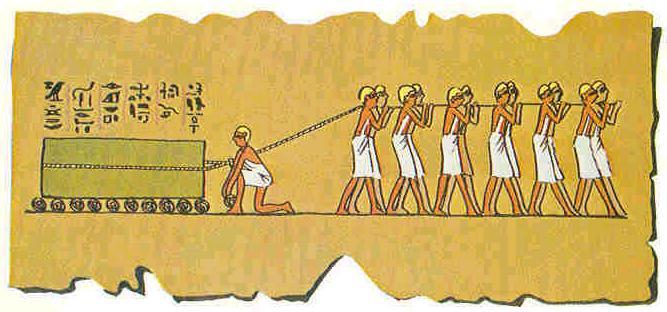

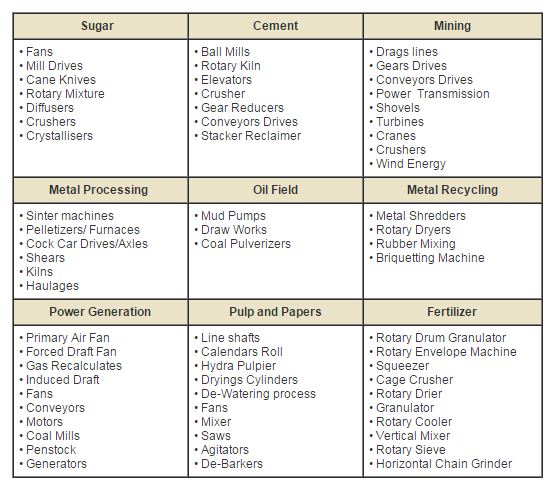

Typical Application

NTN Bearings are designed to operate reliably and cost effectively in continuous operation even in dusty and wet conditions as well as where high temperatures occur, while requiring only minimal maintenance.

Wind Energy

Servicing the wind-energy industries of Asia, Europe, and the United States for years.

NTN’s OEM experience in mature wind markets enable us to apply expert engineering, production, and marketing practices to main shaft, gearbox, and generator projects at any stage of design.

As the OEM supplier to more than ten megawatt-class turbines, NTN offers world-class technical support and a vast product range, creating an unmatched level of customization to suit the needs of any design. Our expertise in spherical, cylindrical, and multi-row tapered roller bearings helps to ensure optimal turbine performance.

Main Shaft

NTN’s asymmetrical roller design is commonly used in pairs at the rotor and generator side of the main shaft. By pushing the rollers into the center inner rib, our products allow for quieter, more smoothly running bearings with low heat generation and, ultimately, longer life. Our cylindrical roller bearings maintain excellent temperature stability by minimizing roller skew under the variable load and speed conditions present in wind turbine applications. New materials and improved heat treatments increase bearing service life. These bearings are available in many cage configurations including steel, brass, resin, and full-complement. For turbine designs that don’t require two main rotor bearings or direct drive turbines, the rotor load is borne by the gearbox bearing alone. In this configuration, double- and triple-row tapered roller bearings provide the necessary radial and axial loading characteristics.

Gearbox

As an essential part of the nacelle, the gearbox must function at peak performance to turn wind into power. When replacement is necessary, NTN tapered and cylindrical bearings help to reduce downtime with their easy assembly. Specialized designs provide both high-speed and high-load-carrying capabilities while maintaining the high level of reliability NTN is known for. NTN bearings can be found in all gearbox applications. From low-speed and high-speed planetary gear drives in main gearboxes to high-speed gear and output shafts, our sophisticated designs meet your requirements. In addition to standard cylindrical roller bearings, NTN has developed technology that combines the high-load capacity of a full complement bearing with the high rotational speed capabilities of a caged design. In ratings tests, the high capacity cylindrical roller bearing attained a life 1.5 times longer than a conventional bearing.

Generator

Wind turbine technology continues to increase equipment efficiency, reliability, and length of service. In an electric environment, electrolytic corrosion from stray currents passing through an improperly grounded shaft can threaten bearing performance. A bearing insulated from electric current can prevent raceway damage and extend generator life.

Ceramic Coated Bearings

MEGAOHM™ bearings feature a special ceramic coating applied to the outer surface and side faces of the outer ring. This coating prevents current from passing though the bearing. MEGAOHM™ bearings are used in OEM applications and provide insulation resistance of at least 2,000 MO under normal operating temperatures.

Ceramic Hybrid Bearings

For especially problematic applications, NTN offers ceramic hybrid bearings. Using conventional steel for the inner and outer rings, silicon nitride rolling elements provide excellent electrical insulation while reducing rotating mass and improving heat dissipation. The unique properties of ceramic rolling elements can also extend service life and extend grease intervals.

Construction

Paving the way for progress and performance in the construction industry.

Heavy equipment is a necessity for every road and bridge-construction project. When industry giants such as Caterpillar and John Deere trust NTN for their bearings, shouldn’t you?

Covering All Applications

NTN bearings can be found in all types of construction equipment, including cranes, hydraulic excavators, asphalt pavers, motor graders, wheel loaders, and off-highway trucks, as well as many other types of heavy equipment used in building projects. NTN‘s diverse product line supports building-equipment repair needs with high-quality bearing products that include:

- - Tapered roller bearings

- - Cylindrical roller bearings

- - Crown blocks

- - Spherical roller bearings

- - Ball bearings

- - Slewing ring bearings

Industry Focused Manufacturing

NTN’s Macomb, IL facility was built in 1965 to support the construction industry.

Its central location in western Illinois was chosen for its proximity to major construction equipment manufacturers. Our long tradition of serving the construction industry gives us a unique understanding of the specific demands of the working environment. This understanding has led to many technical innovations in bearing design, such as special surface finishes to increase lubrication effectiveness and heat treatments that extend bearing life.Agriculture

A major supplier to all OEM agricultural machinery manufacturers in North America.

Broad Application Coverage

Agricultural machinery requires better seals for contaminated conditions, provisions for misalignment, and economical mountings for shafts and housings. NTN offers bearings for disc harrows, planters, mowers, rakes, all types of balers, tillage, seeding and forage harvester equipment, combines, cotton pickers/stripers, and other agricultural equipment like silo unloaders and grain elevators.We also offer a complete line of insert ball bearings, shaft mounted with either tapered adapters or locking collar or set screws. Our proven seal designs include low torque shields to heavy-duty triple lip seals. Disc harrow bearings are also available with either round, square, or hexagonal bores. All bearings are available with or without re-lubrication holes.

A Tradition Of American Made Quality

As a trusted brand in agricultural products for nearly 100 years, NTN is committed to serving American farmers with American-made product manufactured in Macomb, Illinois. We have an ongoing commitment to developing and manufacturing the finest in ball and roller bearings, and we’ve been given the customer quality awards that attest to our reliability and quality.

Local Inventory

In addition to our regular industrial aftermarket stock, our nationwide distribution center guarantees that more than 450 of the most popular agricultural bearings are always in stock, including: ball bearings, flanged disc units, rubber mounted disc bearings, square, hex and round bore bearings, and agricultural bearing inserts.

Automotive

A trusted leader in OEM bearing products for the biggest names in the industry.

The Markey Leader

NTN holds the largest share of the global market for axle bearings, critical automotive components that enable wheel axles to turn. We’re number two in global market share of constant-velocity joints (CVJs), a key component for vehicle drivetrains.

Focus On Efficiency & Envirinment

At NTN, we’re developing smaller, lighter bearings and CVJs that offer lower torque, and we’re stepping up the development of modular products for electrical vehicles. Our goal is to address the latest concerns of the auto industry, such as the need for low-fuel consumption and reductions in CO2 emissions.

Local Production And Local Support

NTN believes that it is important to manufacture product within in the same market that it is sold. We’ve invested millions of dollars in land, facilities, capital equipment, and labor by providing thousands of domestic jobs for NTN employees, our supplier associates, and joint venture partners in the U.S. and Canada. Our ten North American factories have produced millions of automotive bearing and CVJ units for practically every OEM vehicle assembly plant or Tier 1 operation in the nation, as well as for several overseas markets. We continue to grow our local footprint with our Automotive Center located near Detroit. Through our local and global network, NTN is dedicated to providing full service capabilities in design, engineering, product validation, sales, and program management. We’re also driven to deliver optimized CVJ and bearing products that support the unique needs of our North American OEM customers—at the right time, the highest quality, and the best price.

Heavy Duty Truck

Driving superior precision and performance for nearly 100 years.

The Tapered Bearing That OEMS Prefer

NTN BOWER® products are backed with the most stringent quality standards in the industry. All of our unique solutions and proprietary technologies are fueled by our dedication to R&D and supported by our record of high customer satisfaction. For these reasons, many OEMs specify NTN BOWER bearings for their trucks.

Case Hardened, Longer Lasting

Case carburizing is a heat treatment that leaves higher carbon content on the outer surface of the steel product, allowing the core to remain soft and durable. All NTN BOWER tapered roller bearings feature case-carburized rolling elements that greatly increase durability and extend life. As a result, you increase maintenance intervals and reduce downtime.

Product Solution For The Heavy Duty Truck Aftermarket

NTN BOWER products can be found in various heavy duty truck applications including Heavy Duty truck wheel ends to Heavy Duty truck differentials. NTN BOWER supports the heavy duty truck aftermarket with the following products: Bearing Products - |Wheel End Sets - |Clutch Pilot Bearings Kit Products - |Differential Repair KitsAerospace

Making safety our number-one priority in the aerospace industry.

Committed To R&D

NTN’s engagement in the research and development of aircraft bearings responds to various demands of the aerospace industry. Our firm adherence to safety and reliability has earned NTN engine parts their high reputation. As the industry continues to advance, so do the quality and reliability of our bearings.

Jet Engine Bearing

Engine bearings are divided broadly into two categories of use: main shafts and reduction gears (auxiliary drive system). Sophisticated technology is required to design and manufacture main shaft bearings, which are used in high-speed and high-temperature conditions. NTN manufactures and supplies a wide variety of bearings for use in generators, motors, starters, fuel pumps, oil pumps, cabin super chargers, air cycle machines, auxiliary power devices, and other components of aerospace applications. You’ll find NTN main shaft bearings on engines that fly the 747 and 737.

Landing Gear

Aircraft landing gear systems utilize advanced technologies that can endure high shock loads as the planes make contact with the runway.NTN is proud to supply American landing-gear-system manufacturers with case-carburized tapered roller bearings that meet the crucial performance criteria specified by the FAA. Every time a 737 or 767 lands, NTN bearings played a little role in its safe arrival.

Mining And Aggregate

Rock-solid bearing products that meet the rigorous requirements of the industry.

Mining

At the core of every mining operation is a complex array of mining machines, from compact, yet powerful, continuous miners in underground mining to the larger-than-life draglines found in surface mining. Even with some of today’s most complex equipment, mining is still, at its core, a fairly simple process that can be broken down into three basic components: mining, transport and removal. NTN has bearings for each of these processes. With our experience in the mining, construction, agriculture, and heavy-duty truck markets, we have the products capable of performing in the dirty, harsh environments of mines and exceeding reliability and life requirements. We offer complete wheel kits for use on the 10SC and 21SC shuttle cars, available as either a complete kit or components. For conveyor-belt drives, we have a complete line of SAF-style pillow blocks, as well as a complete line of premium spherical roller bearings. Additionally, for continuous miners, we offer a complete line of case-carburized, tapered roller bearings for use in cutter heads and gathering pots.

Processing

One of the toughest industrial equipment applications for bearings is vibrating screens or shaker screens. NTN has developed a special line of spherical roller bearings specifically designed for the severe applications found in shaker screens and all vibrating equipment. NTN Shaker Screen Sphericals have distinct features that make them ideal for vibrating applications:

- - A solid brass cage that is resistant to vibrations and associated failures

- - Higher standard load rating that enhances bearing life

- - Tighter tolerances that ensure proper operation in vibrating applications

Transfer

Heavy contamination has been and will always be a major problem in the aggregate industry. Mining & Aggregate The current sealing arrangement of SAF units often leads to contamination, which ultimately leads to premature failure. Equipment must then be shut down for repairs, increasing overall costs and cutting dollars out of the bottom line. Previously, re-lubrication schedules were the only way to prevent these failures. By flushing out the contaminants, maintenance personnel can overcome the inadequate sealing arrangement. However, this method can drastically increase lubrication costs. NTN’s Heavy Duty Spherical Roller Bearing Mounted Units solve this problem. Available in SPAW, SPW, and SFCW types, these units utilize contact seals to combat heavy contamination issues. The spring-loaded contact seals offer better contamination protection and less grease consumption, while offering greater misalignment capability. Additionally, these units offer the same base-to-shaft-center height and bolt-hole positions as SAF units for easy replacement. Standard one-piece ductile iron housing offers better shock-loading characteristics and quicker mounting and dismounting, when compared to SAF units.

Metal Manufacturing

Withstanding the toughest of operating conditions in metal production.

Rolling Mills

NTN’s roll-neck bearings feature a four-row, taper setup that effectively supports both radial and axial loads. Most bearings are available with seals, and the bearing boxes can be designed in compact configurations since thrust bearings are eliminated. NTN roll-neck bearings are also available with EA™ surface treatment and RustGuard™ corrosion preventative for especially harsh applications. NTN's EA prefix designates the use of case-carburized bearing steel that has a special surface heat treatment modification. This combination gives the bearing significant protection against shock loading, as well as greatly extended fatigue life when operating in contaminated lubrication. If corrosion is a concern, RustGuard™ is a manganese phosphate coating applied to bearing rings and rolling elements. This special coating extends bearing life by up to 100% and is especially effective for controlling downtime-induced rust. So, when your line is ready to start back up, you can be sure your bearings are too.

Continuous Casting Machines

Continuous casting machines subject bearings to some of the most extreme conditions possible. Bearings face high temperatures, high loads, low speeds, and water splash. With dimensional stability up to 200° C, a high capacity for misalignment, and the highest load rating in the industry, NTN high-load capacity sphericals are an ideal solution to the unique demands of casters.

Safs Pillow Blocks

SAFS type pillow blocks are made of high-quality cast steel in a two-piece split design for ease of installation and inspection. The most modern machining equipment and exacting quality control assure maximum life and reliability. Triple-seal rotating rings eliminate debris ingress, and unique relubrication design channels apply lubricant directly through the housing to the center of the bearing, for immediate penetration to all working surfaces.Machine Tool

Precision bearing lines that meet the most stringent needs for high performance.

Precision, Stiffness, High Speed

From stock removal to high-speed grinding, machine-tool performance is critical in most production processes. When it comes to holding precision tolerances and machining time savings, our line of precision bearings covers the most demanding applications in the market. Our precision lines are used in a diverse range of industries, some of these applications include high-speed medical equipment and woodworking equipment, as well as heavy-industry and automotive engine plants that require the maintenance of precision tolerances. Even the CNC equipment used in our own bearing plants use NTN bearings to perform a variety of grinding, polishing, and stock-removal processing tasks. For applications requiring even higher rotating speed, NTN offers angular contact bearings fitted with ceramic balls. These specific properties allow for increased rotating speeds without overheating, while also improving bearing stiffness and extended life. We use the highest precision processing and measuring technology when we create our high performance products. We also offer a wide range of ball-screw supports, double-direction angular contact and cylindrical roller bearings, and precision SNR locknuts.

Technical features include:

- - Universal or matched bearing sets

- - Very high quality 100 Cr6 steel rings and balls

- - Contact angles of 15°, 17° and 25° (SNR range)

- - Contact angles of 15°, 30°, 40° and 60° (NTN range)

- - Four pre-load levels

- - Sealed-for-life angular contact precisions

- - Laminated resign cage (phenolic) centered on inner ring (SNR standard)

- - Nylon-resign cage (NTN standard)

- - Machined brass cage (NTN standard for cylindrical precision)

- - Precision grades of ISO4 (P4) and ISO2 (P2), and additional grades available upon request

- - Bore ranges from 10mm up to 240mm

- - OD ranges up to 420mm

Rail And Transit

Serving all of the major U.S. transit authorities—and Japan’s high-speed bullet train.

Rail

As more and more commuters turn to public transportation, NTN is always working to provide new and improved ways to assist local and worldwide transportation systems. NTN supplies a large number of tapered roller bearings for gearbox, wheel, and journal applications, as well as ceramic-coated bearings for traction-motor applications. NTN built its foundation in the rail industry on tapered roller bearings for gearbox applications. These tapered roller bearings are made at NTN-Bower® facilities in the United States. They are designed to support both axial and radial loads, as well as to withstand excess vibration produced by small and large gears. Our standard case-carburized steel offers a forty percent longer bearing life, helping to make NTN the best in the business. Our diverse product line also features insulated bearings specifically designed for trail-traction motors. These ceramic or resin-coated bearings counteract damage caused by electrical currents in rail-car motors. NTN offers insulated bearings in a wide variety of bore diameters.

Bus

The NTN-Bower® brand is a top choice for major transit authorities across the country. From New York City to Los Angeles and Orlando to Philadelphia, the largest, most stringent organizations demand our bearings for their fleets. OEMs in the bus market turn to us because NTN-Bower products are backed with the most stringent quality standards in the industry. Then comes our record of high customer satisfaction and our dedication to R&D, which translates into unique solutions, proprietary technologies, and bearing products that provide the most durability, the longest life, and the highest performance.

Food Processing

Providing the durability and flexibility required for food-grade environments.

Stainless Steel Series

Mounted bearing units with a stainless composition are designed specifically for applications where corrosion resistance is mandatory. When subjected to environments featuring high humidity or the presence of corrosive cleaning agents, traditional cast-iron ball bearing units are more likely to degrade at a faster rate during conveyor-line-washdown cycles. To address this issue, NTN’s Stainless Steel series features full stainless steel composition, from outer housing to inner ball bearings and raceways. The solid base construction of NTN Stainless Steel bearings offers superior mount stability and impact-load resistance than bearings with semi-solid construction do. In addition, the removal of additional cavities minimizes any space in which particle buildup can occur. Mounted unit solutions are available in a wide array of configurations, including pillow block and two- or four-bolt flange styles. Protective endcaps can be ordered for additional protection, and are universal to all Stainless Steel series mount styles. All stainless steel units feature grease that meets the USDA H1 food-grade specification. NTN also offers solid-grade equivalent greases for higher temperature applications.

Thermoplastic Series

The NTN Thermoplastic series offers comparable performance to our Stainless Steel series, but with added focus on protection from mold, bacteria, and chemical cleaning agents. Housings feature a white PBT composition that is designed with smooth surfacing to prevent particle buildup and retention. The Thermoplastic series offers similar solid-base construction to the Stainless Steel series, meaning excellent mount stability and impact resistance. With pillow block, flange, and endcap availability similar to those featured in the Stainless Steel series, the Thermoplastic series provides you optimum flexibility when selecting the appropriate bearing unit for your application. Thermoplastic units also feature USDA H1 grade grease, as well as a stainless-steel bearing unit insert composition that offers exceptional humidity resistance.

Ultra-Class Series

NTN’s flagship, mounted-unit line provides an excellent offering for food processing applications that don’t require assembly line washdown. The Ultra-Class line is the original solid-base offering in our mounted bearing unit portfolio and has come to symbolize NTN’s commitment to performance and reliability. Featuring NTN’s exclusive ball-point, set-screw design, the Ultra-Class black-oxide-plated insert provides 120° screw orientation, meaning superior alignment and centering when compared to typical 90° configurations. The semi-retractable, ball-point mechanism enables excellent tightening torque characteristics without damaging the shaft-mounting surface. Protection from particles in pharmaceutical or dry-good environments is paramount when selecting a mounted unit solution, and the Ultra-Class series is up to the task. Using a combined elastomeric seal, in tandem with NTN’s outer flinger design, each mounted unit exhibits a fan-like mechanism that effectively keeps particles away from the inner ball bearing and raceways.

Committed To Innovation

Our product lines are optimal solutions for an environmentally demanding industry, and we are committed to collaborative development of new and unique solutions for the dynamic rules and regulations of the industry. Contact your local NTN representative today, and find out how we can assist with your unique design requirements.

Infrastructure

Offering a wide array of products for a wide array of projects.

Wastewater Treatment

From industrial facilities to municipal water supplies, wastewater treatment plants must run continuously. A heavy emphasis on predictive and preventative maintenance can keep you ahead of the curve, but only if premium replacement parts are used. NTN manufactures a broad range of quality bearing products to ensure trouble-free operation. With specialized bearing solutions, we’ve got you covered on a full spectrum of rotating equipment in wastewater treatment:

- - Spherical and case-carburized tapered roller bearings for pumps

- - Sealed ball bearings for aerators and rotating screens

- - Corrosion-resistant bearing units for conveyors

- - Insulated bearings for variable speed drive motors and fans

Ports, Inland Waterways, And Dams

Ports, inland waterways, and dams are home to some of the harshest and most demanding conditions. Moisture ingress, rust, and heavy loads can all lead to early bearing failure. To withstand these difficult conditions and provide longer bearing life, NTN offers case-carburized tapered roller bearings, spherical roller bearings, and cylindrical roller bearings. NTN’s crown block tapered roller bearings are often found in overheard container cranes at ports—cranes that are often subjected to heavy loads of up to 65 tons and are susceptible to corrosion from nearby salt water. Crown block bearings are produced at the NTN-Bower® facilities in Illinois and Alabama and feature our case-carburized steel, which adds up to 40% onto the life of your bearings. Damage to dams is most often caused by moisture and heavy pressure loads from the water. To combat these issues in applications such as dam gates, sluices, and gearboxes, NTN offers case-carburized tapered roller bearings, cylindrical roller bearings, and spherical roller bearings with the highest load rating in the industry. We also manufacture a full line of ball bearings and premium Ultra Class™ mounted units for use in ports, inland waterways, and dams.

p>Airports

Baggage- and cargo-handling systems move literally tons of luggage and packages every hour. And since airlines and passengers count on these complex systems to quickly and safely move their cargo through the terminal, breakdowns are simply not acceptable. These systems require high-quality ball bearings, roller bearings and mounted units to ensure safe, smooth, and reliable operation. To meet these demanding requirements, NTN offers a wide range of ball bearings and mounted bearing units. Our top-of-the-line Ultra-Class mounted units combine a land-riding, rubber-lip seal and flinger with optional, black-oxide coating to provide superior protection against contaminants and corrosion. Ultra-Class units also have a solid base housing built for harsh environments that deal with heavy loads. NTN’s electric, motor-grade ball bearings provide smooth, quiet operation to ensure that motors and conveyor equipment are operating at peak efficiency. Ball bearings are available in both sealed and open versions to meet the needs of any cargo-handling application.