ADVANTAGES

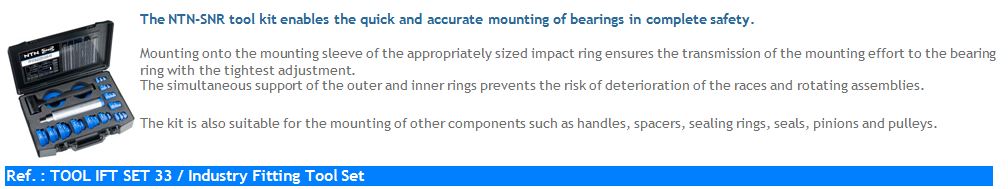

Of light and strong construction for workshop use, this toolbox contains:

-33 impact rings

-3 mounting sleeves

-1 special dead blow mallet, ensuring optimum impact

ADVANTAGES

ADVANTAGES

ADVANTAGES

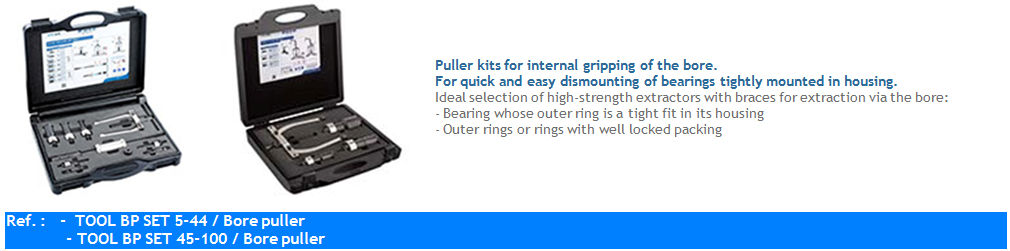

Robust

-Pullers designed in 2 parts and manufactured in special, strong, break and wear-resistant steel, ensuring a long life

-Arms in carbonitride steel not requiring any special maintenance

Ergonomic

-Mechanical spindle with handle

Wide range of use

-BP Set 12-45 includes 6 pullers for 12 to 45 mm bore diameters -BP Set 35-100 includes 4 pullers for 35 to 100 mm bore diameters

Each kit is supplied in a solid steel case

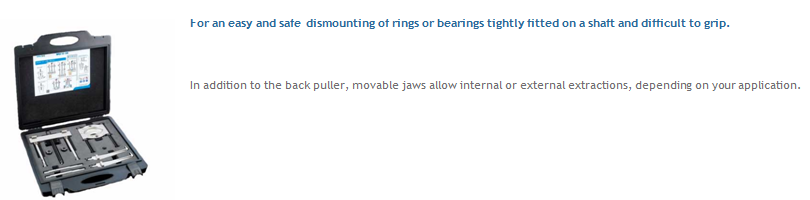

The set, supplied in a strong steel case, includes:

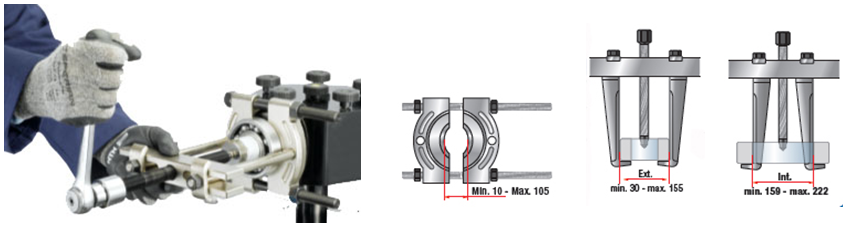

- a back puller with a 100kN capacity mechanical spindle and 2-blade separator to separate and grip rings and bearings from behind with a diameter of between 10 and 105 mm

- two extension rods for quick adaptation to the required pulling length

- two movable jaws allowing internal (bore Ø 159-222mm) and external extractions(external Ø 30-155mm)

For optimum use, turning the separator, after separation by tightening the two blades, enables greater force to be exerted without deforming the blades, for the complete extraction of the part

ADVANTAGES

ADVANTAGES

ADVANTAGES

Deep groove ball bearing puller set

All components of the kits are made in a special, strong and wear-resistant steel, to ensure a long life. BBPS 10-100 contains an easy-to-understand universal user manual and 22 identified rings to facilitate the right choice of accessories.

The kit also provides 3 « O » rings to ease the fastening of the arms on the spindle for a quick tool assembly.

ADVANTAGES

Hydraulic nuts

ADVANTAGES

Besides the hydraulic principle, the "back and forth” design provides unique ease of operation with the automatic return of the thrust plate to the original position (patented NTN-SNR design.

The right questions to ask yourself when selecting a hydraulic nut:

ADVANTAGES

ADVANTAGES

ADVANTAGES

ADVANTAGES

ADVANTAGES

The LASER TEMP 301 thermometer combines safety with accuracy.

Its elaborate optical system allows small, remote targets to be measured easily and precisely.

ADVANTAGES

Supplied with: Type K thermocouple wire probe (range -50°C to +440°C, length 1m)

Protective pouch - User manual

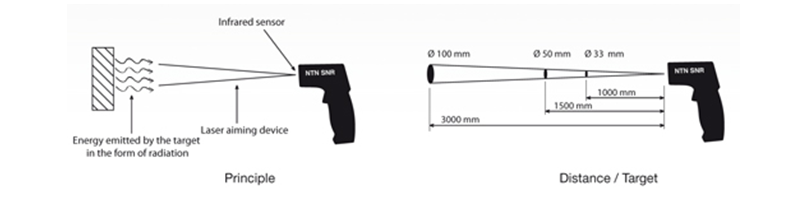

Infrared thermometer, how it works?

Infrared thermometers measure the surface temperature of an object.

The unit’s optics sense emitted, reflected and transmitted energy, which is collected and focused onto a detector. The unit’s electronics translate the information into a temperature reading, which is displayed on the unit. The laser pointer is only used for aiming the target.