Mounting, Dismounting & Handling

Recommendations:

- Check bearing identifying marks against drawings, specifications and procedures.

- Check that bearing seat dimensions and the accuracy of their shape and position correspond to SNR drawings and specifications.

- Prepare all equipment, tools and parts required before starting the mounting. Ensure that everything is clean.

- Carefully clean and check all parts and devices in the bearing's environment.

- Remove the bearing from its packaging at the last moment in a completely clean working area.

- Never wash it, except in specified exceptional cases. The bearing is protected from oxidation by a light film of oil compatible with all lubricants.

- Mount the bearing, using the chosen method.

- Lubricate, using a special bearing grease, following the instructions given.

- After mounting and before final start-up, check its operation, so as to detect any possible anomalies (noise, vibrations, temperature, abnormal play, etc.).

The words of an NTN-SNR expert:

For easier mounting and to avoid contact corrosion of the shaft or the housing, always use an anti-fretting paste. This thick lubricant helps preserve the quality of parts surfaces subjected to sliding forces. Without this paste, corrosion will gradually increase the play between the bearing and the shaft (or housing), ultimately causing vibration and even the premature deterioration of the bearing and its mounting surfaces. Avoid introducing contaminants when mounting (swarf, liquid, etc.).

What is cold mounting?

Cold mounting is the simplest method and is suitable for small and medium-sized bearings, completed with the normal adjustments.

The most frequently observed problems:

- Over- or under-tightening when adjusting

- Excessive impacts during mounting or forces causing rings and seals to break, or races to become indented

- The accidental introduction of particles or liquids present in the mounting environment

Our recommendations

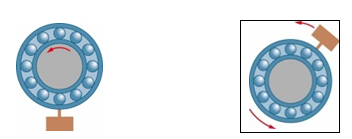

1st rule: The ring that rotates in relation to the load must be tightly mounted on its seat.

Load fixed in relation to the outer ring.

|

|

Load fixed in relation to the inner ring. Outer ring tightened into its housing. |

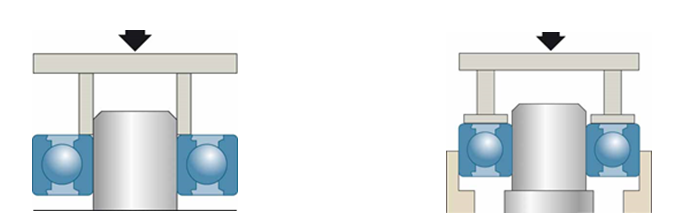

2nd rule: Mounting is carried out using impact rings applied to the bearing ring which has the tightest fit. This avoids stressing the rotating body and damaging the bearing.

Special case of a long shaft for an assembly requiring a longitudinal adjustment of the bearing: it is preferable touse a mechanical coupling with a tapered seat joined to a bearing with a tapered bore.

Special case of a long shaft for an assembly requiring a longitudinal adjustment of the bearing: it is preferable touse a mechanical coupling with a tapered seat joined to a bearing with a tapered bore.

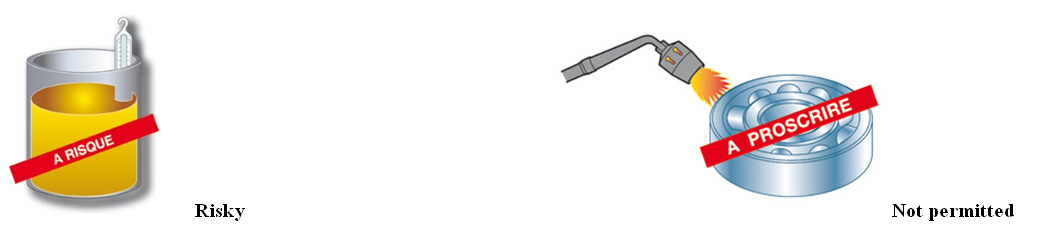

What is hot mounting?

- The mounting of a bearing onto a shaft requires a lot of strength as the size and the fit tolerance increase

- Heating the bearing before installation allows it to to be inserted without forcing on the shaft

- NTN-SNR’s induction heaters provide the best solution in terms of safety, cleanliness and speed compared with oil-bath heating, hot plates or ovens.

The words of an NTN-SNR expert

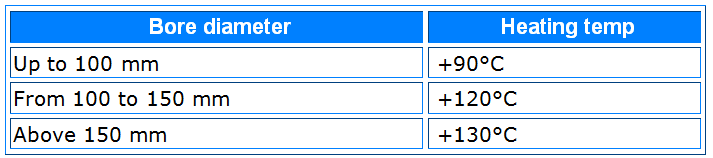

- The temperature must not be too high, so as not to change the characteristics of the steel or the internal components of the bearing (maximum 130°C). On the other hand, it must be sufficient to cause sufficient expansion for the easy installation of the bearing thanks to the temporary loosening.

- The heating temperature is a function of the size, on the one hand and the fit of the seat on the other.

- As a general rule, the following temperatures are recommended:

Use of anti-fretting paste facilitates insertion and protects the shaft or housing from contact corrosion

The wearing of heat insulating gloves is necessary for the safe and comfortable handling of the heated parts.

In the case of heavy bearings, help will be required for their handling.

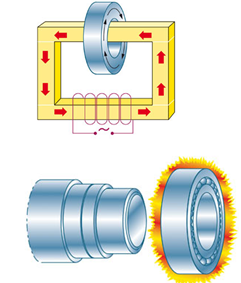

Principle of heating by induction

The device comprises a steel framework surrounded by a coil with a large number of windings. When a current passes through it, this primary coil generates a magnetic field which itself induces an electric current in the bearing (or other steel part), substituted for the secondary coil of an electrical transformer. When a high-intensity, low-voltage AC current passes through it, the bearing heats up quickly while non-metallic parts and the device itself remain cool. Induction heating magnetises the bearing. It is therefore necessary for the heater to demagnetise it at the end of the heating cycle. This avoids steel particles being attracted into the bearing later on.

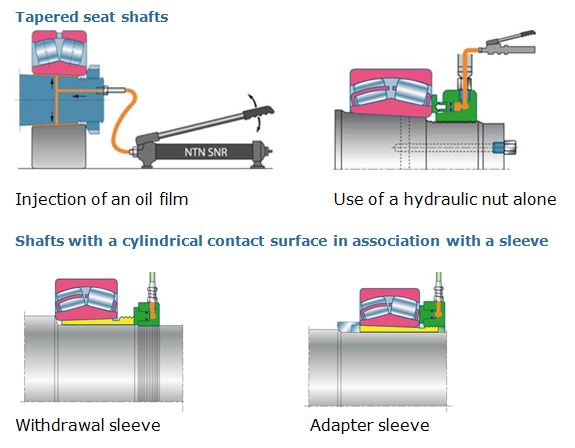

What is hydraulic mounting ?

The mounting of large bearings with a tapered bore requires considerable effort, difficult to achieve using mechanical screw tightening. The use of hydraulic technology is required in such cases.

- Either an oil film is injected over the whole of the contact surface between the shaft and the inner ring. This reduces the friction generated by the mounting and facilitates tightening.

- Or the oil is sent at very high pressure into a hydraulic nut which develops the thrust required for the mounting.

- The two principles may also be used simultaneously to make mounting easier. The residual clearance is checked using feeler gauges or a comparator which measures the embedding on the tapered contact surface.

Two types of mounting lend themselves to this method:

Tapered seat shafts

Dismounting

Disassemble cleanly: Look after your equipment and save time, safely!

By opting for the correct methods and tools, you reduce the risk of personal injury and damaging parts (shaft, housing, even the bearing, if it is to be re-used).

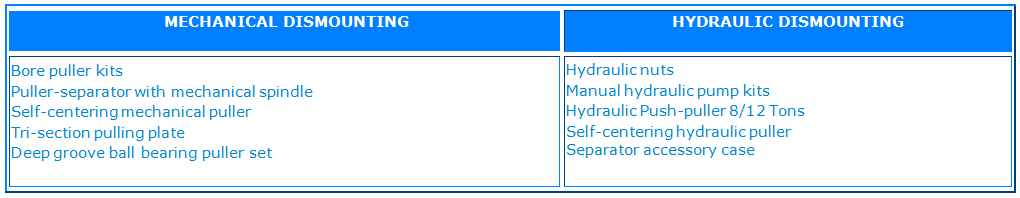

Find out the NTN-SNR maintenance tools offer:

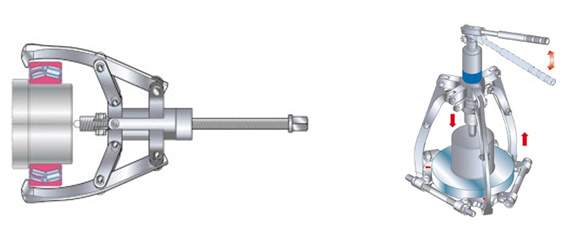

What is mechanical dismounting?

So far as is possible, the best way is to extract the bearing with the ring held firm.

NTN-SNR offers a comprehensive range of extractors easy to use robust and safe to be chosen depending on the grip offered by the bearing, its accessibility and the extraction force required.

Extractors equipped with a pump and hydraulic cylinder allow the operator to develop very high extraction efforts, using his own muscular strength. They are easy to use, due to the fact that their arms are self-centering.

If hydraulic channels were originally provided in the shaft, the injection of a film of oil on the contact surface between the shaft and the inner ring greatly reduces the effort required.

The right questions to ask:

How do I grip the part? Selection of the type of grip: external, internal or special

What is the diameter of the part to be extracted? Enables the seat, spread and force to be defined.

How do I pull on the part? Choice of a support point: on the central shaft, on the outside of the part or using extraction accessories.

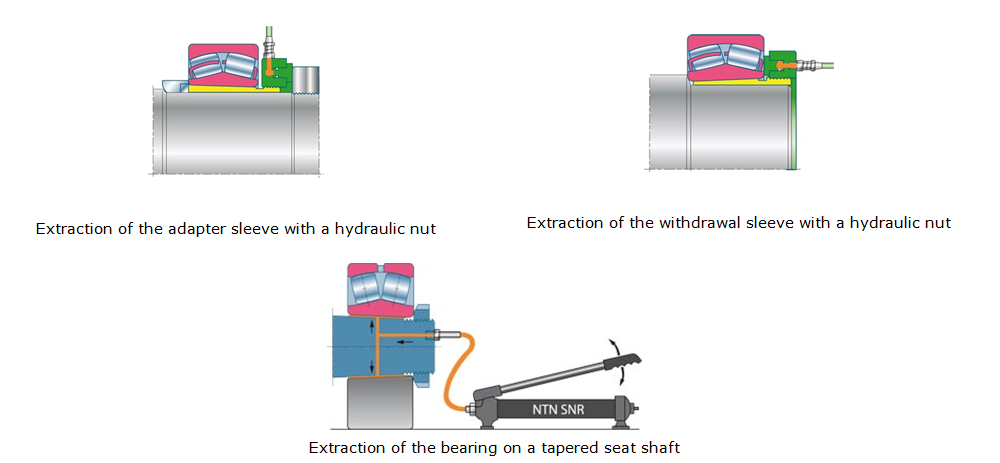

What is hydraulic dismounting?

When the dimensions of mechanical parts are large, and it is necessary to use high efforts for extraction, it is better to choose hydraulic techniques.

The NTN-SNR hydraulic nut is an ideal tool for a quick and easy dismounting of bearings mounted on the adapter or withdrawal sleeve.

Handling

Bearing Mounting Surfaces

Any burrs, cutting chips, rust or dirt should first be removed from the bearing mounting surfaces. Installation can then be simplified if the clean surfaces are lubricated with spindle oil.

Preparation Procedure

Burrs, dirt, and other contaminants that infiltrate the bearing before and during mounting will cause noise and vibration during subsequent operation.

Mounting Equipment

Ensure that all pressing blocks, driving plates, hammers and other mounting devices are clean, free of burrs, and of the correct size

Do not Unwrap Bearings until just prior to Mounting

Do not make any modifications to the products

Bearings are manufactured to very tight tolerances in order to meet extremely high accuracy requirements. Therefore, it is imperative to take special precautions with regard to their handling.

Mounting Procedures and Examples of Damage

.gif)

Furthermore, the maximum static load that bearings can withstand is shown in the NTN catalog as the bearing's “basic static load rating.” This is the maximum amount of force which can be applied to the central contact area between rolling elements and raceway surfaces. If exceeded, total permanent deformation exceeding 1/10,000 of the bore diameter will result, and smooth bearing rotation will be impaired. This is the basis for establishing the basic static load ratings.

★ Mounting bearings using a hammer causes damage due to sharp impacts. Please mount press fit bearings using a pressing arbor or other designed to provide a uniform face.

.gif)

.gif)

Bearing Care

Bearings are very susceptible to impacts and shock loads!

Bearings carry their loads along an extremely narrow contact surface between the rolling elements and the inner and outer raceway surfaces.

If an excessive load or impact is applied to this narrow area of contact, brinelling and/or scarring will occur. This damage leads to objectionable noise and vibration levels and rough bearing rotation. (Even dropping bearings on the floor will cause this type of damage.

Bearings are very susceptible to foreign particle contamination!

If foreign particles infiltrate the bearing during rotation, denting and/or scarring will occur and this will lead to poor bearing rotation and excess noise.

Temperature Mounting (Heat expansion of inner ring to ease installation.

Commonly used for large bearings and bearings with a heavy interference fit.

- Immersion of the bearing in heated oil is the most common method. Use clean oil and suspend the bearing in the oil with a wire or support it underneath using a metal screen in order to avoid uneven heating of bearing elements.

- The temperature to which the inner ring should be heated depends upon the amount of interference fit i.e. the diameter of the interference fit surfaces. Refer to the following graph to determine the proper temperature.

- To prevent gaps from occurring between the inner ring and shaft shoulder, bearings which have been heated and mounted on the shaft should be held in place until they have cooled completely.

Observe these precautions when heating bearings

- Bearings should never be heated over 120°C.

- This temperature mounting method cannot be used for pre-greased and sealed bearings or shielded bearings.

Other heating methods

- Bearing Oven

Bearings are dry. This method can also be used for pre-greased bearings.

When using this method with pre-greased bearings, do not heat the bearings above 120°C - Induction Heating

This method can also be used for the inner rings of cylindrical roller bearings. Bearings are dry and can be heated up in a short period of time.

After using this method, administer a demagnetizing treatment to the bearing. For more detailed information concerning bearing heating methods, contact NTN.

Bearing Oven