What the expert say:

Only appropriate lubrication can guarantee the optimal operation of bearings and the related mechanical assembly. Only appropriate lubrication can guarantee the optimal operation of bearings and the related mechanical assembly. 55% of premature bearing failure is caused by inappropriate lubrication. Inadequate lubrication will substantially shorten the service life of the bearing. Bearing lubrication is often neglected due to the difficulty of accessing bearings and the operator's lack of lubricant knowledge. Selecting the right lubricant, the right lubrication method, the precise quantity required for the bearing and the frequency of monitoring the lubrication are all critical points.

Principle and benefits of good lubrication

Lubrication is an integral part of the bearing.

The service life of the bearing is directly related to the effectiveness of the oil film, which depends on:

- the type of lubricant, its specific heat capacity, resistance to vibrations, etc.

- the load and speed of the bearing.

NTN-SNR has carried out research in this field with the leading international lubricant manufacturers for more than half a century.

We therefore have knowledge and practical experience for most lubricants used with bearings.

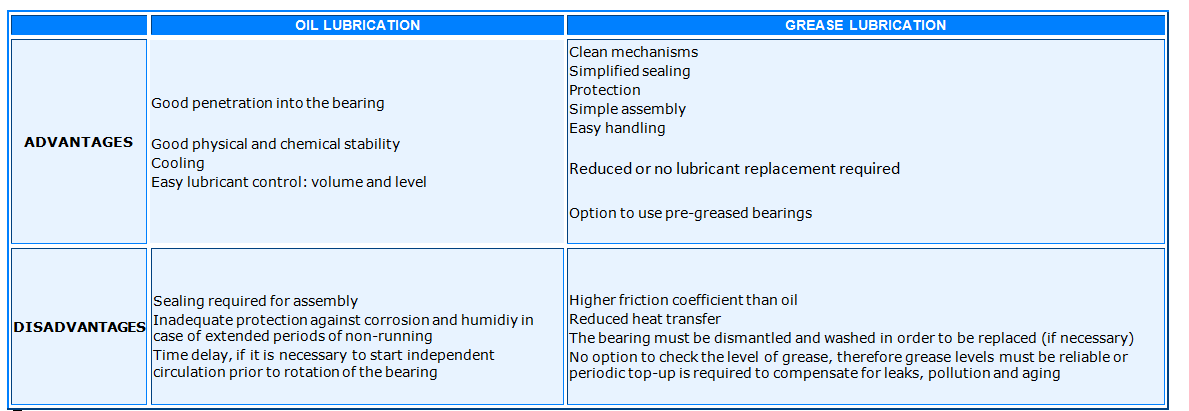

Selecting your type of lubrication

LUB'SOLUTIONS

is above all a team of experts ready to assist you in implementing the right solutions for your environment. Our technicians are available to solve your problems, from providing advice in defining your requirements to installing lubrication systems for your application, including made-to-measure projects.LUB'SOLUTIONS

the Experts & Tools way of thinking. Our experts are available and determined to provide you with customized solutions to ensure that your bearings and machines operate in optimal conditions, applying their Experts & Tools way of thinking.Increase the service life of your bearings thanks to NTN-SNR greases

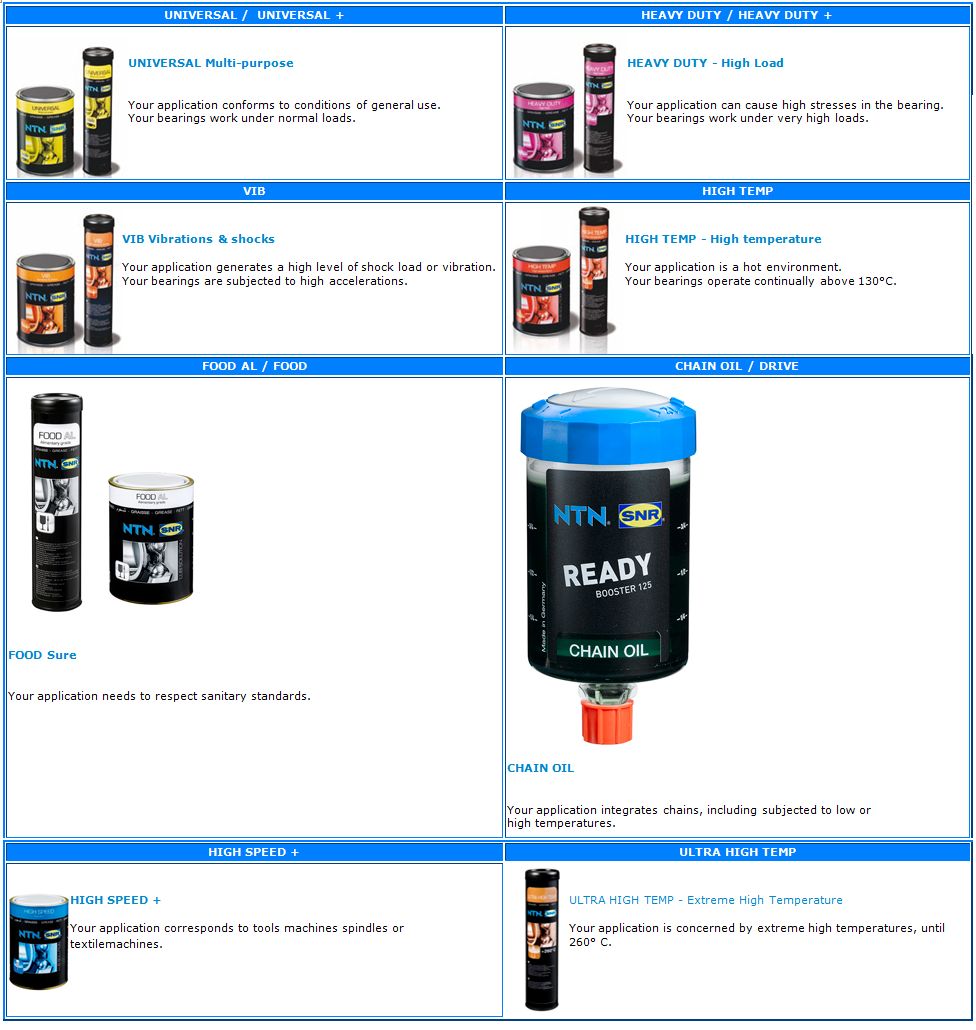

The new NTN-SNR professional greases supply was especially developed for bearings and contented most of 95% current applications. This simplified range is available depending on your application, allowing you to increase on the service life of your bearings.

Choose the adapted grease

NTN-SNR simplifies your choice with its range of professional greases.

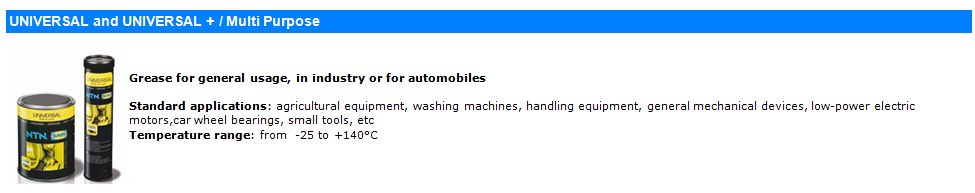

Discover the NTN-SNR range of greases

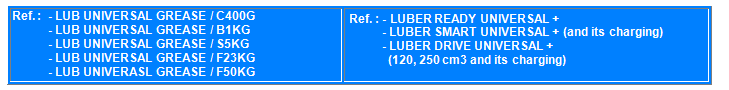

*Universal + is a lubricant adapted to centralized lubrication system, with same performances but slightly modificated to be dispensed with an automatic lubrication system.

BENEFITS

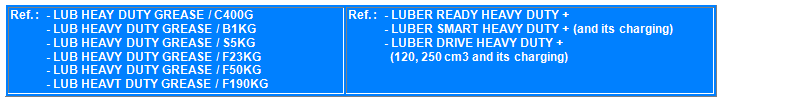

*Heavy Duty + is a lubricant adapted to centralized lubrication system, with same performances but slightly modificated to be dispensed with an automatic lubrication system

BENEFITS

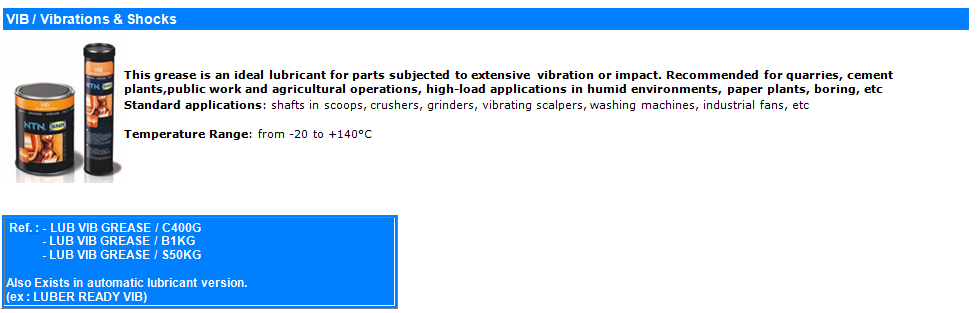

BENEFITS

BENEFITS

BENEFITS

BENEFITS

BENEFITS

BENEFITS